Fibres & Fabrics

Fabric Switch: The Leather Guide

CO's Fabric Switch Guides

This guide is part of CO's suite of Pro content - but has been made available for free to all CO members for a limited time.

If you'd like to access more content like this, take a look at the benefits of Pro Membership.

But first, start scrolling through this guide for a preview of Pro content.

CO's Fabric Switch Guides

This guide is part of CO's suite of Pro content - but has been made available for free to all CO members for a limited time.

If you'd like to access more content like this, take a look at the benefits of Pro Membership.

But first, start scrolling through this guide for a preview of Pro content.

Key Facts

- China is the leading buyer, processor and exporter of leather and leather goods.

- The Global Leather Goods Market is expected to reach $306.1 Billion by 2027.

- Footwear has a 60% market share of all finished leather products.

- The global synthetic leather market was valued at USD 31.4 billion in 2020, according to Grand View Research and is predicted to be worth $86 billion by 2025.

Key Facts

- China is the leading buyer, processor and exporter of leather and leather goods.

- The Global Leather Goods Market is expected to reach $306.1 Billion by 2027.

- Footwear has a 60% market share of all finished leather products.

- The global synthetic leather market was valued at USD 31.4 billion in 2020, according to Grand View Research and is predicted to be worth $86 billion by 2025.

Key Issues in Leather

1. Animal welfare

An estimated 3.8 billion animals are used to make leather each each year.

Whilst there are ethical issues around the use of any animal product in fashion, and in leather’s origins as a by-product of the meat industry, even for non-vegetarians and non-vegans there are animal exploitation issues to consider.

This includes the conditions under which they are reared, raised and slaughtered.

Key Issues in Leather

1. Animal welfare

An estimated 3.8 billion animals are used to make leather each each year.

Whilst there are ethical issues around the use of any animal product in fashion, and in leather’s origins as a by-product of the meat industry, even for non-vegetarians and non-vegans there are animal exploitation issues to consider.

This includes the conditions under which they are reared, raised and slaughtered.

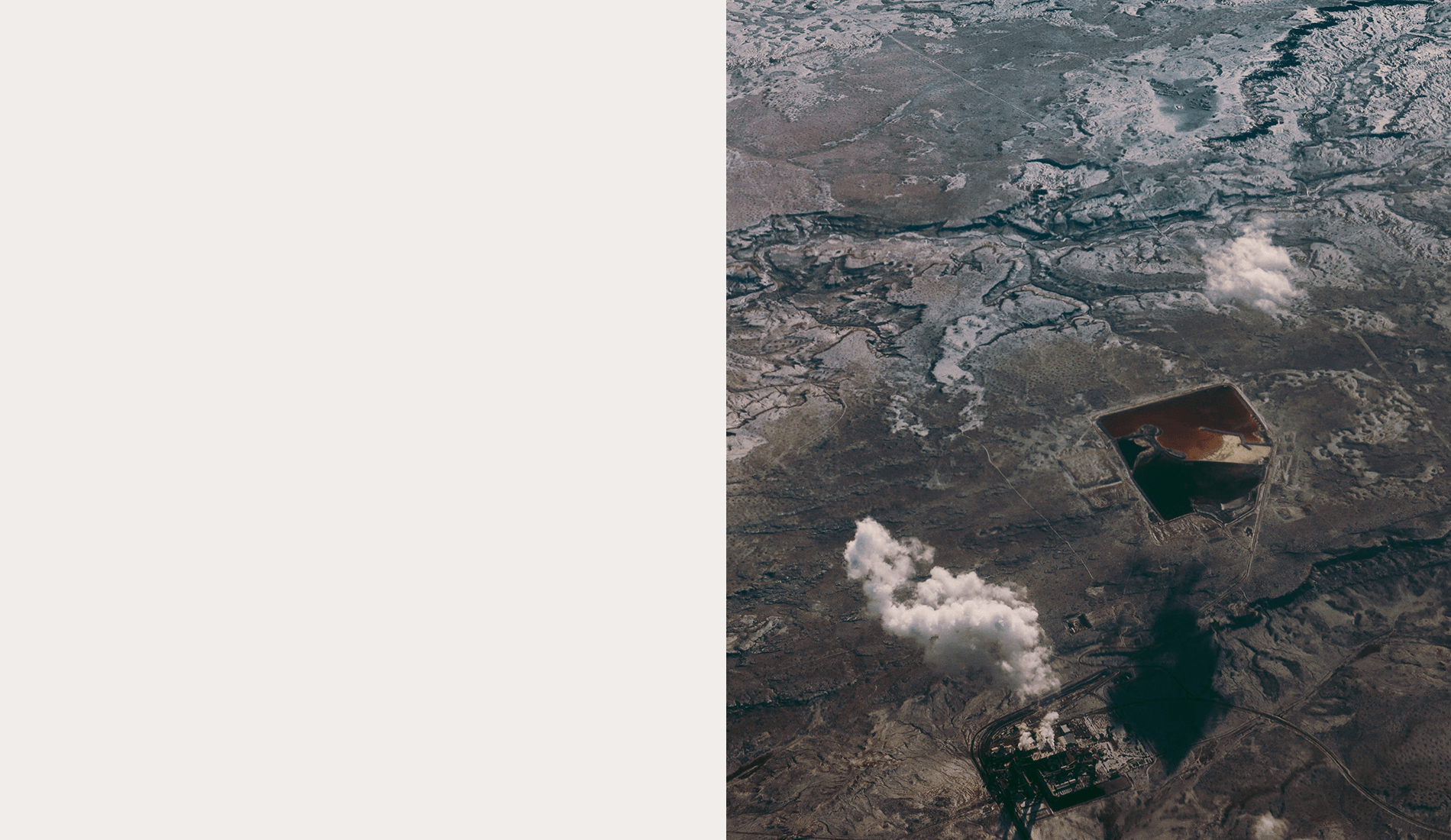

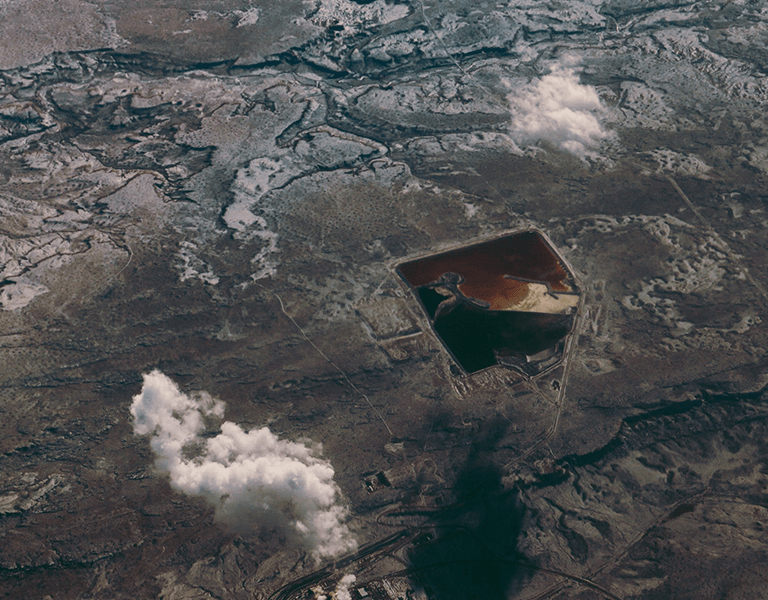

2. Environmental impact of leather

Extensive farming of livestock – the origin of most leather – has severe environmental impacts, such as deforestation, water, land-overuse and carbon emissions.

The leather tanning process, used to stop hides from decomposing, traditionally involves a toxic slush of noxious chemicals and gases, including carcinogenic chromium which often flows directly into local waterways in countries with poor regulations or enforcement. The US and Europe, however, do have strict regulations on chromium waste.

Read more in Fibre Briefing: Leather.

2. Environmental impact of leather

Extensive farming of livestock – the origin of most leather – has severe environmental impacts, such as deforestation, water, land-overuse and carbon emissions.

The leather tanning process, used to stop hides from decomposing, traditionally involves a toxic slush of noxious chemicals and gases, including carcinogenic chromium which often flows directly into local waterways in countries with poor regulations or enforcement. The US and Europe, however, do have strict regulations on chromium waste.

Read more in Fibre Briefing: Leather.

3. Human impact

Working in a tannery is extremely hazardous – especially in places where workplace protections are few or non-existent.

In many places, workers – including children as young as 10 – often have little protective equipment or clothing. As well as injury from heavy machinery, they risk exposure to highly toxic chemicals and gases.

Tanneries have also been found which use bonded labour.

Image: Video - The Toxic Price of Leather by Sean Ghallagher - scroll down to watch

3. Human impact

Working in a tannery is extremely hazardous – especially in places where workplace protections are few or non-existent.

In many places, workers – including children as young as 10 – often have little protective equipment or clothing. As well as injury from heavy machinery, they risk exposure to highly toxic chemicals and gases.

Tanneries have also been found which use bonded labour.

Image: Video - The Toxic Price of Leather by Sean Ghallagher - scroll down to watch

The Leather Working Group

Where to begin when searching for suppliers of sustainable leather? The Leather Working Group (LWG) is a good starting point.

A multi-stakeholder group of brands, suppliers, manufacturers, NGOs and end users, LWG uses a protocol to gauge compliance and environmental practices within the leather industry.

The Leather Working Group

Where to begin when searching for suppliers of sustainable leather? The Leather Working Group (LWG) is a good starting point.

A multi-stakeholder group of brands, suppliers, manufacturers, NGOs and end users, LWG uses a protocol to gauge compliance and environmental practices within the leather industry.

Industry veterans - Pittards

Based in south-west England, Pittards is a long-established leather producer with trading links to Ethiopia that date back nearly 100 years.

The firm, which produces leather and finished products, provides community-wide support for Pittards' employees in Ethiopia – such as an on-site clinic and resources for schools.

Most of Pittards’ Ethiopian-made leather is shipped to premium brands – including Berghaus, Footjoy, Ona Polo – making it the leading leather exporter in Ethiopia.

Industry veterans - Pittards

Based in south-west England, Pittards is a long-established leather producer with trading links to Ethiopia that date back nearly 100 years.

The firm, which produces leather and finished products, provides community-wide support for Pittards' employees in Ethiopia – such as an on-site clinic and resources for schools.

Most of Pittards’ Ethiopian-made leather is shipped to premium brands – including Berghaus, Footjoy, Ona Polo – making it the leading leather exporter in Ethiopia.

Chemical-free tanning

1. Vegetable tanning

Leather was not always produced with heavy chemicals. Ancient Greeks to Victorians tanned hides using vegetable tannins extracted from bark, wood and leaves.

Vegetable tanning produces far less harmful waste, and a finished leather product that is biodegradable. It takes much longer than chemical processing but it is being revived due to consumer demand.

Brands on CO using vegetable tanning include Miljours Studio (pictured) and O My Bag.

Chemical-free tanning

1. Vegetable tanning

Leather was not always produced with heavy chemicals. Ancient Greeks to Victorians tanned hides using vegetable tannins extracted from bark, wood and leaves.

Vegetable tanning produces far less harmful waste, and a finished leather product that is biodegradable. It takes much longer than chemical processing but it is being revived due to consumer demand.

Brands on CO using vegetable tanning include Miljours Studio (pictured) and O My Bag.

2. Vegetable Tanning Associations

The Tanners Extract Producers Federation (TEPF) is dedicated to spreading best practice among tanners to promote vegetable leather use for designers and consumers. Search their directory here

The Genuine Italian Vegetable Tanned Leather Consortium brings together 20 Italian tanneries who can use the trademark “Pelle Conciata al Vegetale in Toscana”.

2. Vegetable Tanning Associations

The Tanners Extract Producers Federation (TEPF) is dedicated to spreading best practice among tanners to promote vegetable leather use for designers and consumers. Search their directory here

The Genuine Italian Vegetable Tanned Leather Consortium brings together 20 Italian tanneries who can use the trademark “Pelle Conciata al Vegetale in Toscana”.

Aside from traditional barks there has recently been innovation in using other plant materials to tan leather.

3. Rhubarb tanning

The German company Deepmello developed and sell leather tanned using rhubarb instead of chromium.

They have found that it makes a soft hand-feel leather and is so safe it can be used in children's and babywear; plus it's biodegradable.

Aside from traditional barks there has recently been innovation in using other plant materials to tan leather.

3. Rhubarb tanning

The German company Deepmello developed and sell leather tanned using rhubarb instead of chromium.

They have found that it makes a soft hand-feel leather and is so safe it can be used in children's and babywear; plus it's biodegradable.

4. Smooth as an olive

Moore & Giles’ Olive Green leather refers not to its colour but the fact it’s tanned using olive leaves - a by-product of olive farming.

The wet-green® process that they use carries CradletoCradle™ GOLD certification and is also LEED v4 compliant.

4. Smooth as an olive

Moore & Giles’ Olive Green leather refers not to its colour but the fact it’s tanned using olive leaves - a by-product of olive farming.

The wet-green® process that they use carries CradletoCradle™ GOLD certification and is also LEED v4 compliant.

Other animal skins

Fish and other animal leathers have similar environmental, social, and animal welfare issues as leathers made from cows, goats, or sheep.

Similarly, if you are looking to work with these, it is best to look out for vegetable-tanned skins without toxic chemicals that have been harvested or reared sustainably.

Atlantic Leather offer vegetable-tanned salmon leather - suitable for bags and accessories.

Nova Kaeru is the world's first organic tannery producing Pirarucu fish leather.

Other animal skins

Fish and other animal leathers have similar environmental, social, and animal welfare issues as leathers made from cows, goats, or sheep.

Similarly, if you are looking to work with these, it is best to look out for vegetable-tanned skins without toxic chemicals that have been harvested or reared sustainably.

Atlantic Leather offer vegetable-tanned salmon leather - suitable for bags and accessories.

Nova Kaeru is the world's first organic tannery producing Pirarucu fish leather.

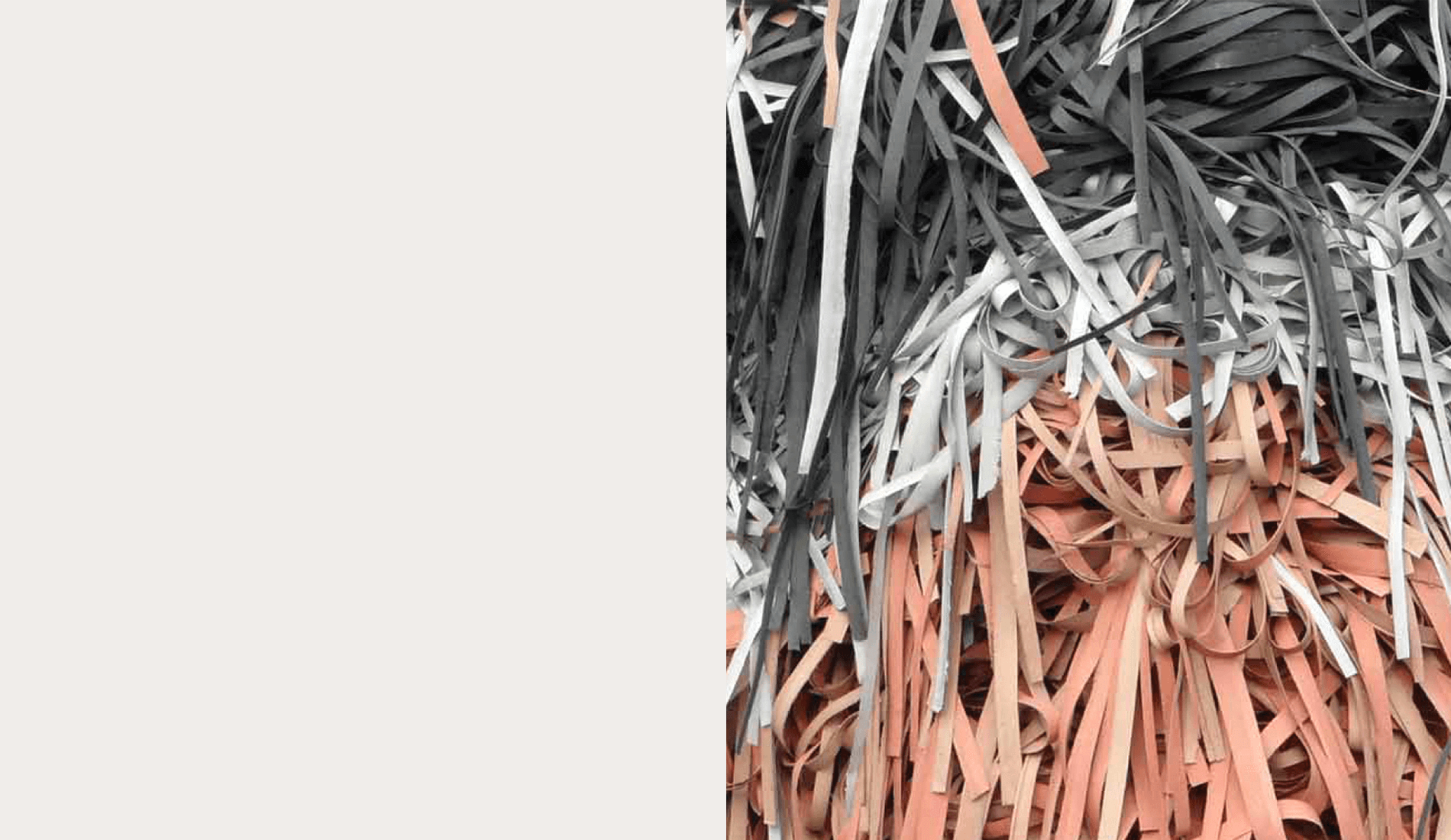

Closing the leather loop

With 35% of pre-consumer supply chain waste and 80% of consumer waste going to landfill or incineration, there is huge opportunity to recycle fibres and materials into new.

RecycLeather uses leather offcuts and scraps to create new materials that can be turned into fashion or home accessories.

UK-based E-Leather produces a recycled composition leather that is used for upholstery and leather accessories. Their patented technology combines leather fibres and offcuts without the use of toxic adhesives.

Closing the leather loop

With 35% of pre-consumer supply chain waste and 80% of consumer waste going to landfill or incineration, there is huge opportunity to recycle fibres and materials into new.

RecycLeather uses leather offcuts and scraps to create new materials that can be turned into fashion or home accessories.

UK-based E-Leather produces a recycled composition leather that is used for upholstery and leather accessories. Their patented technology combines leather fibres and offcuts without the use of toxic adhesives.

Bio-leathers

1. Piñatex

Philippines-based Piñatex leather by Ananas Anam derives from pineapple leaves – an agricultural by-product usually left to rot.

Piñatex was the first fruit leather to gain traction with international brands including Camper and Ally Capellino.

Brands on CO using Piñatex include PETA-approved accessories brand Ahimsa Collective (pictured) and footwear brand Po-Zu.

Bio-leathers

1. Piñatex

Philippines-based Piñatex leather by Ananas Anam derives from pineapple leaves – an agricultural by-product usually left to rot.

Piñatex was the first fruit leather to gain traction with international brands including Camper and Ally Capellino.

Brands on CO using Piñatex include PETA-approved accessories brand Ahimsa Collective (pictured) and footwear brand Po-Zu.

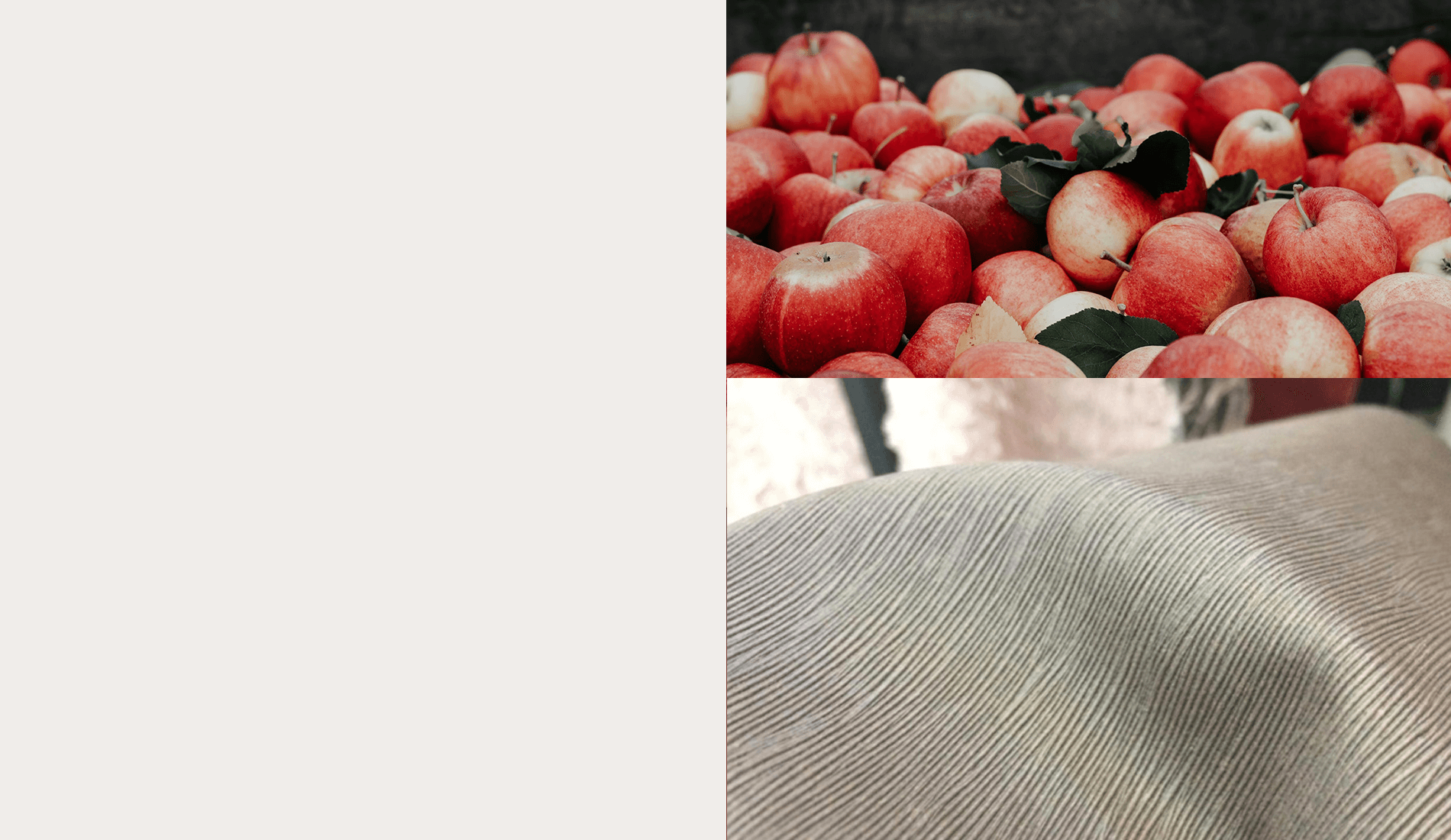

2. Apple Leather

Frumat's Pellemella uses apple pectin, an industrial waste product, to create a sustainable leather-like material.

The finished product is completely compostable whilst still being durable enough to create luxury accessories.

The leathers can be dyed naturally and tanned without chemically-intensive techniques.

2. Apple Leather

Frumat's Pellemella uses apple pectin, an industrial waste product, to create a sustainable leather-like material.

The finished product is completely compostable whilst still being durable enough to create luxury accessories.

The leathers can be dyed naturally and tanned without chemically-intensive techniques.

3. Treekind by Biophilica

Treekind is made from urban plant waste, it can be recycled or turned into compost with no plastic binders.

It uses less than 1% of the water in leather production. It is non-toxic, estimated carbon-negative, and contains ZERO plastic.

Biophilica plans to begin pilot production in late 2021.

3. Treekind by Biophilica

Treekind is made from urban plant waste, it can be recycled or turned into compost with no plastic binders.

It uses less than 1% of the water in leather production. It is non-toxic, estimated carbon-negative, and contains ZERO plastic.

Biophilica plans to begin pilot production in late 2021.

4. Seaweed and Mushroom Leathers

Still at a relatively small scale, innovation in seaweed and mushroom leathers are starting to gain traction.

Muskin, Mycotex, and Mycoworks - all make individual pieces of leather derived from mycelium. Its anti-bacterial properties give it the potential to develop into a material suitable for people with sensitive skin.

Seaweed leather is also at proof-of-concept stage - find out more in the video below.

4. Seaweed and Mushroom Leathers

Still at a relatively small scale, innovation in seaweed and mushroom leathers are starting to gain traction.

Muskin, Mycotex, and Mycoworks - all make individual pieces of leather derived from mycelium. Its anti-bacterial properties give it the potential to develop into a material suitable for people with sensitive skin.

Seaweed leather is also at proof-of-concept stage - find out more in the video below.

5. Grown in a Lab

Also new to market are bio-based leathers grown in a lab from collagen - which could have the potential to produce a finished product that looks and feels a lot more like animal-based leathers.

Zoa™ from Modern Meadows was released at the Museum of Modern Art (MoMa) exhibit, "Items: Is Fashion Modern?"

Meanwhile, Provenance BioFabrics have partnered with UC San Francisco's Gartner Laboratory to further develop their technology with the aim of creating a commercial leather equivalent for the textile industry.

5. Grown in a Lab

Also new to market are bio-based leathers grown in a lab from collagen - which could have the potential to produce a finished product that looks and feels a lot more like animal-based leathers.

Zoa™ from Modern Meadows was released at the Museum of Modern Art (MoMa) exhibit, "Items: Is Fashion Modern?"

Meanwhile, Provenance BioFabrics have partnered with UC San Francisco's Gartner Laboratory to further develop their technology with the aim of creating a commercial leather equivalent for the textile industry.

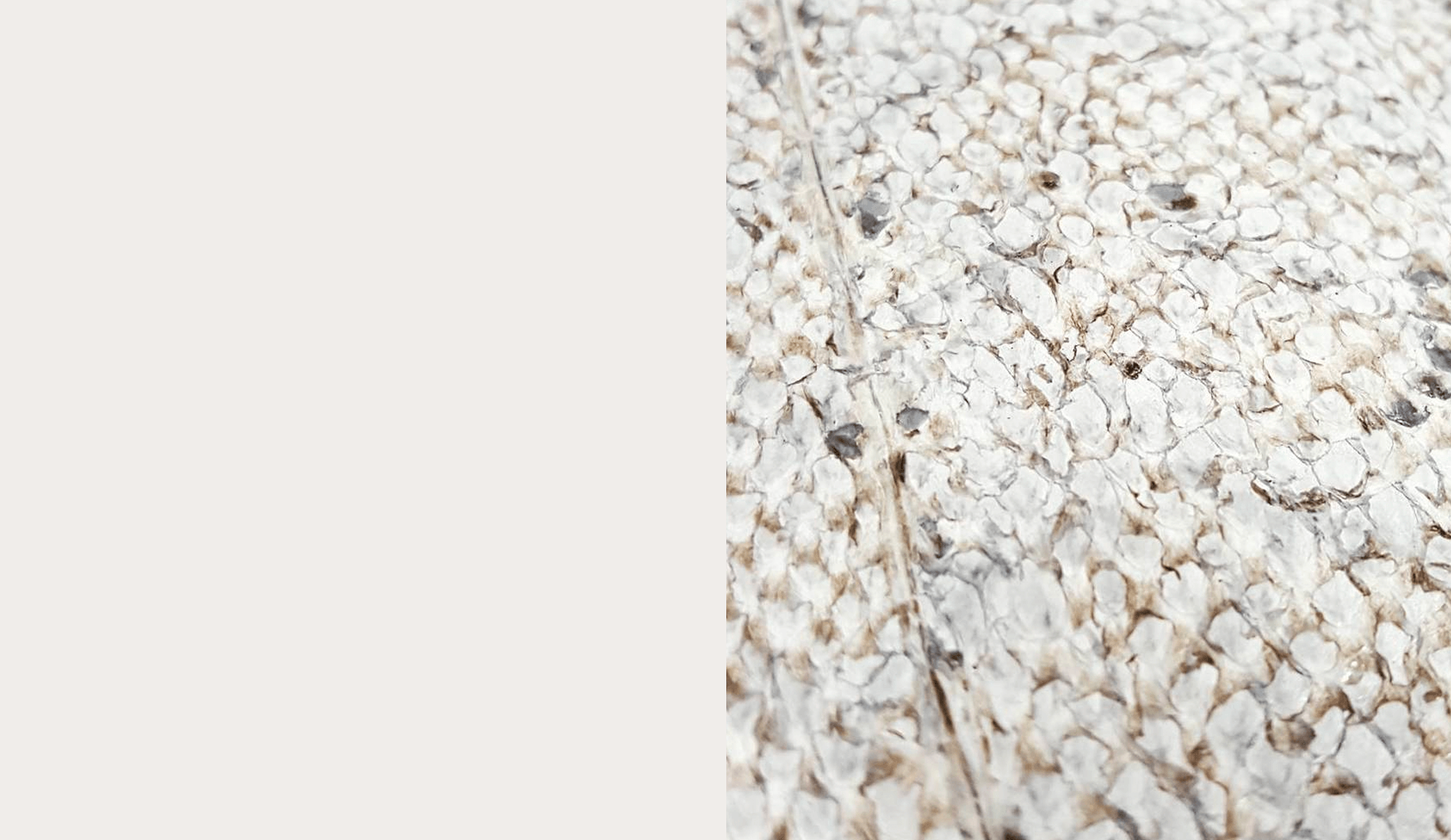

Cork and bark leather

Ono Collaborations (pictured) from Switzerland offers a unique cork-tencel fabric which is durable and liquid-resistant, making it suitable for outerwear.

Queork produce cork fabric from Mediterranean Cork Oak trees. Known as ‘nature’s leather’, the cork is used for accessories, and is naturally hypoallergenic, waterproof and anti-fungal.

Ugandan-German family business Bark Cloth produce bark-fibre leather, from 98 per cent plant-based materials with polymer reinforcing, for apparel and interiors.

Cork and bark leather

Ono Collaborations (pictured) from Switzerland offers a unique cork-tencel fabric which is durable and liquid-resistant, making it suitable for outerwear.

Queork produce cork fabric from Mediterranean Cork Oak trees. Known as ‘nature’s leather’, the cork is used for accessories, and is naturally hypoallergenic, waterproof and anti-fungal.

Ugandan-German family business Bark Cloth produce bark-fibre leather, from 98 per cent plant-based materials with polymer reinforcing, for apparel and interiors.

Leaf Leather

In 2019, Brazilian supplier Nova Kaeru launched beLEAF ™ technology, an organically tanned, plant-based leather made from the giant leaves of the Elephant Ear plant, creating a vegan biotype with characteristics similar to leather. In the same year, beLEAF ™ received the APFL Award in the "Best Natural Material" .

Leaf Leather

In 2019, Brazilian supplier Nova Kaeru launched beLEAF ™ technology, an organically tanned, plant-based leather made from the giant leaves of the Elephant Ear plant, creating a vegan biotype with characteristics similar to leather. In the same year, beLEAF ™ received the APFL Award in the "Best Natural Material" .

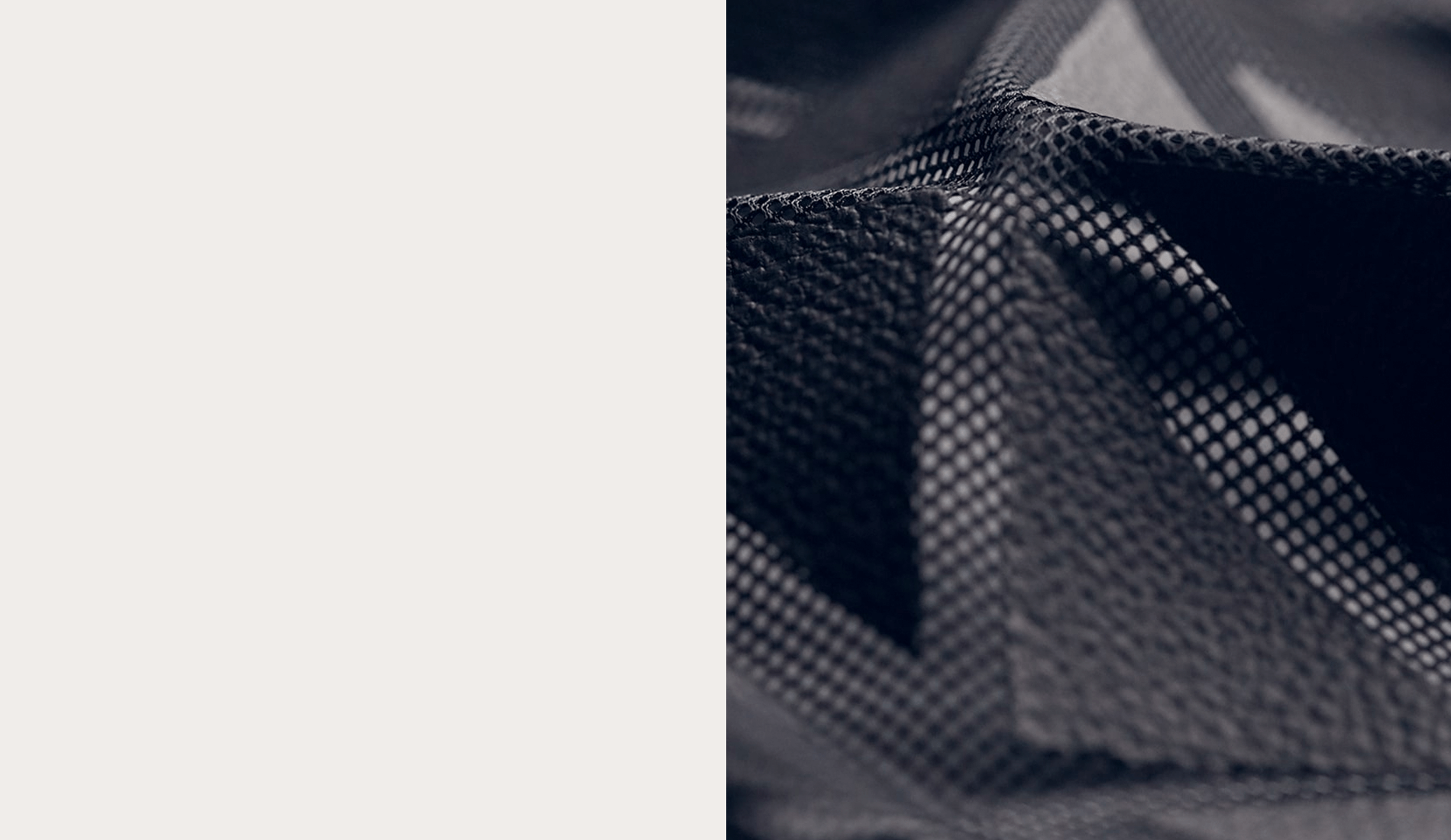

Synthetic alternatives

Polyester-based alternatives to leather – chiefly PVC (polyvinyl chloride), or PU (polyurethane) – have existed for years, posing their own environmental problems. But recycled polyester offers a slightly more sustainable solution.

International chemicals group Toray uses polyester from pre-consumer waste (and, since 2015, plant-based polymers) to produce Ultrasuede, (pictured) a microfibre in a range of thicknesses and colours.

And Dinamica is a microfibre suede created by Italy’s Miko using non-toxic dyes and recycled polyester.

Synthetic alternatives

Polyester-based alternatives to leather – chiefly PVC (polyvinyl chloride), or PU (polyurethane) – have existed for years, posing their own environmental problems. But recycled polyester offers a slightly more sustainable solution.

International chemicals group Toray uses polyester from pre-consumer waste (and, since 2015, plant-based polymers) to produce Ultrasuede, (pictured) a microfibre in a range of thicknesses and colours.

And Dinamica is a microfibre suede created by Italy’s Miko using non-toxic dyes and recycled polyester.

Enjoy this guide?

Upgrade to Pro for more

Discover more of CO's Fabric Switch pieces - including guides on silk, cotton, polyester, stretch, viscose, and interlinings, thread and more - by upgrading to Pro membership.

Access the other Fabric Switch guides in this series here.

Enjoy this guide?

Upgrade to Pro for more

Discover more of CO's Fabric Switch pieces - including guides on silk, cotton, polyester, stretch, viscose, and interlinings, thread and more - by upgrading to Pro membership.

Access the other Fabric Switch guides in this series here.

First published 29.11.2018 - Updated 15.12.2021

Related Reading

Sign up to connect with 50,000+ other sustainability-minded professionals and access over 300 pieces of actionable intelligence.

Common Objective is a global sourcing and information network that enables you to succeed in sustainable fashion business.