Fibres & Fabrics

Fabric Switch: Sourcing Sustainable Denim Suppliers

Sustainability is in season

"The selling point for everyone is sustainability, and everyone is talking about how much they can give back to the environment"

- Harshana Perera, Pacific Jeans at Kingpins Denim Show 2019

Sustainability is in season

"The selling point for everyone is sustainability, and everyone is talking about how much they can give back to the environment"

- Harshana Perera, Pacific Jeans at Kingpins Denim Show 2019

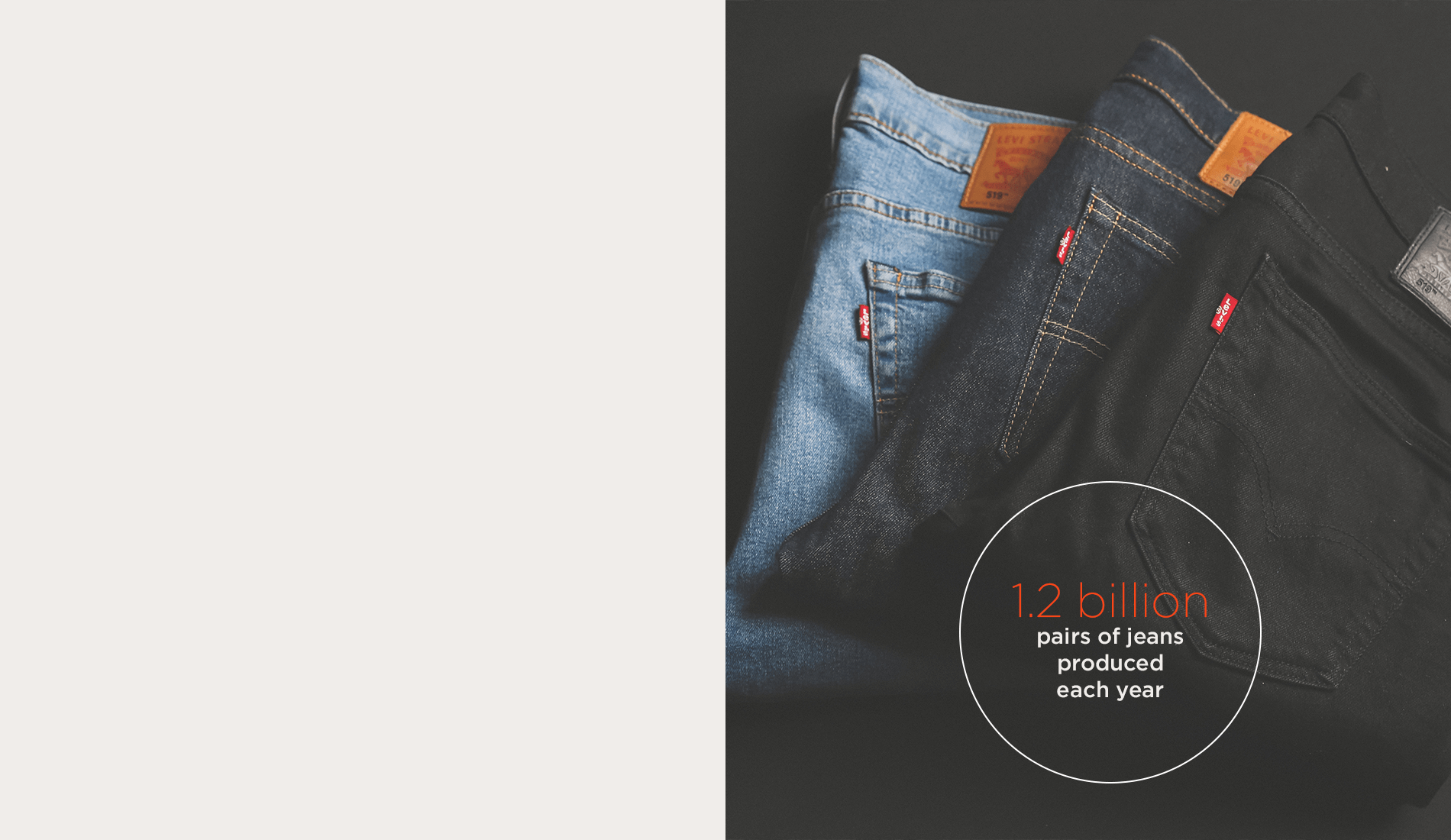

A key sector

The denim industry has a global market size of £44.9 billion ($56.2 billion) with around 1.2 billion pairs of jeans being produced each year.

“Globally, denim is growing quickly and much of that is thanks to the proliferation of streetwear, which has toughened the aesthetic casual-dressing away from the fluid lines of athleisure." - Katie Smith, Retail & Insights Director, Edited

Notably, online fashion search engine Lyst, reported a 187% increase in page views for sustainable denim brands in 2018.

A key sector

The denim industry has a global market size of £44.9 billion ($56.2 billion) with around 1.2 billion pairs of jeans being produced each year.

“Globally, denim is growing quickly and much of that is thanks to the proliferation of streetwear, which has toughened the aesthetic casual-dressing away from the fluid lines of athleisure." - Katie Smith, Retail & Insights Director, Edited

Notably, online fashion search engine Lyst, reported a 187% increase in page views for sustainable denim brands in 2018.

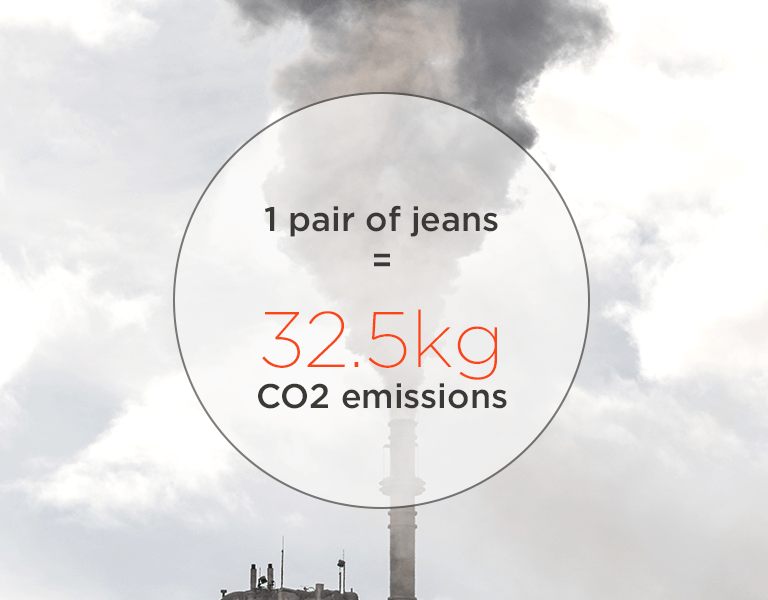

Environmental impact of denim

Over its lifetime, a pair of jeans consumes on average 10,850 litres of water and causes 32.5kg of CO2 emissions – from growing the cotton, to processing, dyeing, finishing, shipping and once bought, washing.

The Higg Materials Sustainability Index calculates that conventionally grown cotton, used in most denim, has roughly double the environmental impact of organic cotton.

And, toxic run-off from denim dyeing processes is polluting waterways.

Environmental impact of denim

Over its lifetime, a pair of jeans consumes on average 10,850 litres of water and causes 32.5kg of CO2 emissions – from growing the cotton, to processing, dyeing, finishing, shipping and once bought, washing.

The Higg Materials Sustainability Index calculates that conventionally grown cotton, used in most denim, has roughly double the environmental impact of organic cotton.

And, toxic run-off from denim dyeing processes is polluting waterways.

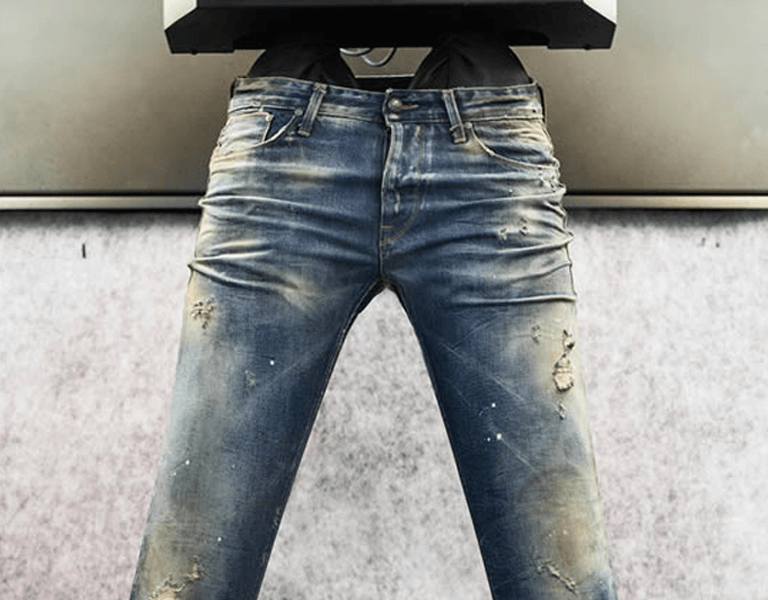

Health impacts

After high profile campaigns and reports about the impacts on health of using sandblasting as a technique to get distressed effects the industry has responded both with brands banning its use in their supply chains and through new processes.

Technical innovation from companies like Jeanalogia and Tonello mean creative finishes are now possible using lasers instead of sand.

Denim dyeing, which made rivers run blue in production areas, has also innovated with waterless and foam dyeing now possible.

Health impacts

After high profile campaigns and reports about the impacts on health of using sandblasting as a technique to get distressed effects the industry has responded both with brands banning its use in their supply chains and through new processes.

Technical innovation from companies like Jeanalogia and Tonello mean creative finishes are now possible using lasers instead of sand.

Denim dyeing, which made rivers run blue in production areas, has also innovated with waterless and foam dyeing now possible.

Switch to organic cotton

Changing from conventional to organic cotton could save up to 3,000 litres of water and at least 2.5 kg of CO2 in producing a pair of jeans.

Ask your current supplier, search the Global Organic Textile Standard database or scroll down and read below for eight organic denim suppliers to suit all denim qualities.

Click here, to find out more about the cost of certification.

Switch to organic cotton

Changing from conventional to organic cotton could save up to 3,000 litres of water and at least 2.5 kg of CO2 in producing a pair of jeans.

Ask your current supplier, search the Global Organic Textile Standard database or scroll down and read below for eight organic denim suppliers to suit all denim qualities.

Click here, to find out more about the cost of certification.

Switch to Fairtrade cotton

Ensure farmers get a fair price for their cotton with Fairtrade cotton denim.

Fairtrade supplier, India’s Anubha Industries produce a wide selection of denim from craft weaves to stretch.

Click here, to find out more about the cost of certification.

Images: Fairtrade

Switch to Fairtrade cotton

Ensure farmers get a fair price for their cotton with Fairtrade cotton denim.

Fairtrade supplier, India’s Anubha Industries produce a wide selection of denim from craft weaves to stretch.

Click here, to find out more about the cost of certification.

Images: Fairtrade

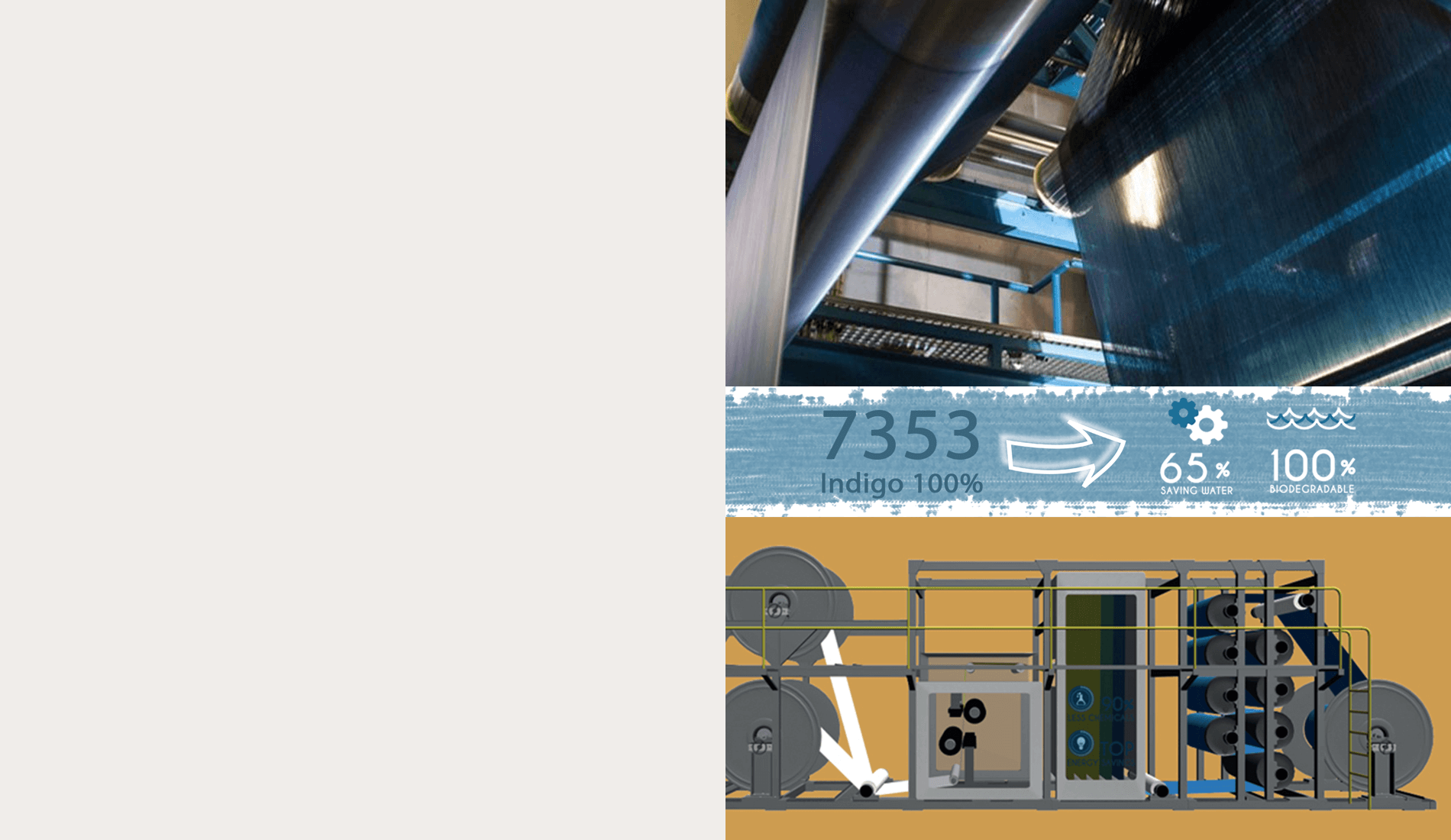

Better denim dyeing

Give the waterways a break with Tejidos Royo’s “Dry Indigo” - denim dyed with a water-free process saving both water and chemicals.

This innovative new machine produces high intensity colour without the huge amounts of water usually used in the dyeing process.

Finishes are also available in other hues of blue, black, brown, and khaki.

Image: Tejidos Royo

Better denim dyeing

Give the waterways a break with Tejidos Royo’s “Dry Indigo” - denim dyed with a water-free process saving both water and chemicals.

This innovative new machine produces high intensity colour without the huge amounts of water usually used in the dyeing process.

Finishes are also available in other hues of blue, black, brown, and khaki.

Image: Tejidos Royo

Better denim dyeing

Officina +39’s innovative Recycrom dye is made from textile waste transformed into fine powder suitable for pigment dyeing.

Whereas Ama Herbal’s Bio Indigo is GOTS certified, comes in a powder form suitable for industrial processes and, they say, just 1kg of dye provides a day’s wages for two South Indian villagers.

Image: Recycrom

Better denim dyeing

Officina +39’s innovative Recycrom dye is made from textile waste transformed into fine powder suitable for pigment dyeing.

Whereas Ama Herbal’s Bio Indigo is GOTS certified, comes in a powder form suitable for industrial processes and, they say, just 1kg of dye provides a day’s wages for two South Indian villagers.

Image: Recycrom

Circular denim

Global Denim’s Eco Loop range is made from recycled scraps from the mill’s own production as well as post-consumer waste. Launched with a rigid version, the mill has since added a stretch variation and has two more planned for SS20.

AMC in Thailand has recycled denim from damaged jeans. The jeans are shredded before being spun and dyed back into new yarns.

Berto Italy use their production waste in making the PIANETA denim collection with a 65% water saving.

Image: Eco Loop

Circular denim

Global Denim’s Eco Loop range is made from recycled scraps from the mill’s own production as well as post-consumer waste. Launched with a rigid version, the mill has since added a stretch variation and has two more planned for SS20.

AMC in Thailand has recycled denim from damaged jeans. The jeans are shredded before being spun and dyed back into new yarns.

Berto Italy use their production waste in making the PIANETA denim collection with a 65% water saving.

Image: Eco Loop

Better denim processing

Italian mill Candiani has long been using Kikotex technology to reduce its energy, water and chemical consumption by up to 70 per cent. They now have a vegan version, Kitotex Vegetal.

Brazil’s Vicuna Denim’s Absolut Eco line saves up to 95 percent water and up to 90 percent on chemicals.

Soorty, Pakistan's largest vertically integrated denim manufacturer, have waterless dyeing and zero water finishing.

Image: Candiani

Better denim processing

Italian mill Candiani has long been using Kikotex technology to reduce its energy, water and chemical consumption by up to 70 per cent. They now have a vegan version, Kitotex Vegetal.

Brazil’s Vicuna Denim’s Absolut Eco line saves up to 95 percent water and up to 90 percent on chemicals.

Soorty, Pakistan's largest vertically integrated denim manufacturer, have waterless dyeing and zero water finishing.

Image: Candiani

Sustainable denim finishing

Pizarro laundries in Portugal have created a safe, affordable alternative to sandblasting.

Ecoblast uses an abrasive with very low silica content in premises and conditions specifically designed for workers’ safety.

Scroll down to watch a video about the process.

Image: Pizarro

Sustainable denim finishing

Pizarro laundries in Portugal have created a safe, affordable alternative to sandblasting.

Ecoblast uses an abrasive with very low silica content in premises and conditions specifically designed for workers’ safety.

Scroll down to watch a video about the process.

Image: Pizarro

Alternatives to cotton

New fibres

Even sustainable cotton still has an impact on the planet. An increasing number of denim mills are blending innovative sustainable fibres such as Lenzing’s TencelTM (made from white pine) and REFIBRATM (cotton scraps plus wood fibre).

See a list of suppliers below who offer REFIBRATM denim.

Alternatives to cotton

New fibres

Even sustainable cotton still has an impact on the planet. An increasing number of denim mills are blending innovative sustainable fibres such as Lenzing’s TencelTM (made from white pine) and REFIBRATM (cotton scraps plus wood fibre).

See a list of suppliers below who offer REFIBRATM denim.

Alternatives to cotton

Hemp

Hemp grows with very little water and produces a robust yarn perfect for denim.

Atlantic Mills (AMC) have a hemp denim range whilst Qingdao Fab Mill and Shanxi Greenland Textiles offer hemp-cotton blends.

Alternatives to cotton

Hemp

Hemp grows with very little water and produces a robust yarn perfect for denim.

Atlantic Mills (AMC) have a hemp denim range whilst Qingdao Fab Mill and Shanxi Greenland Textiles offer hemp-cotton blends.

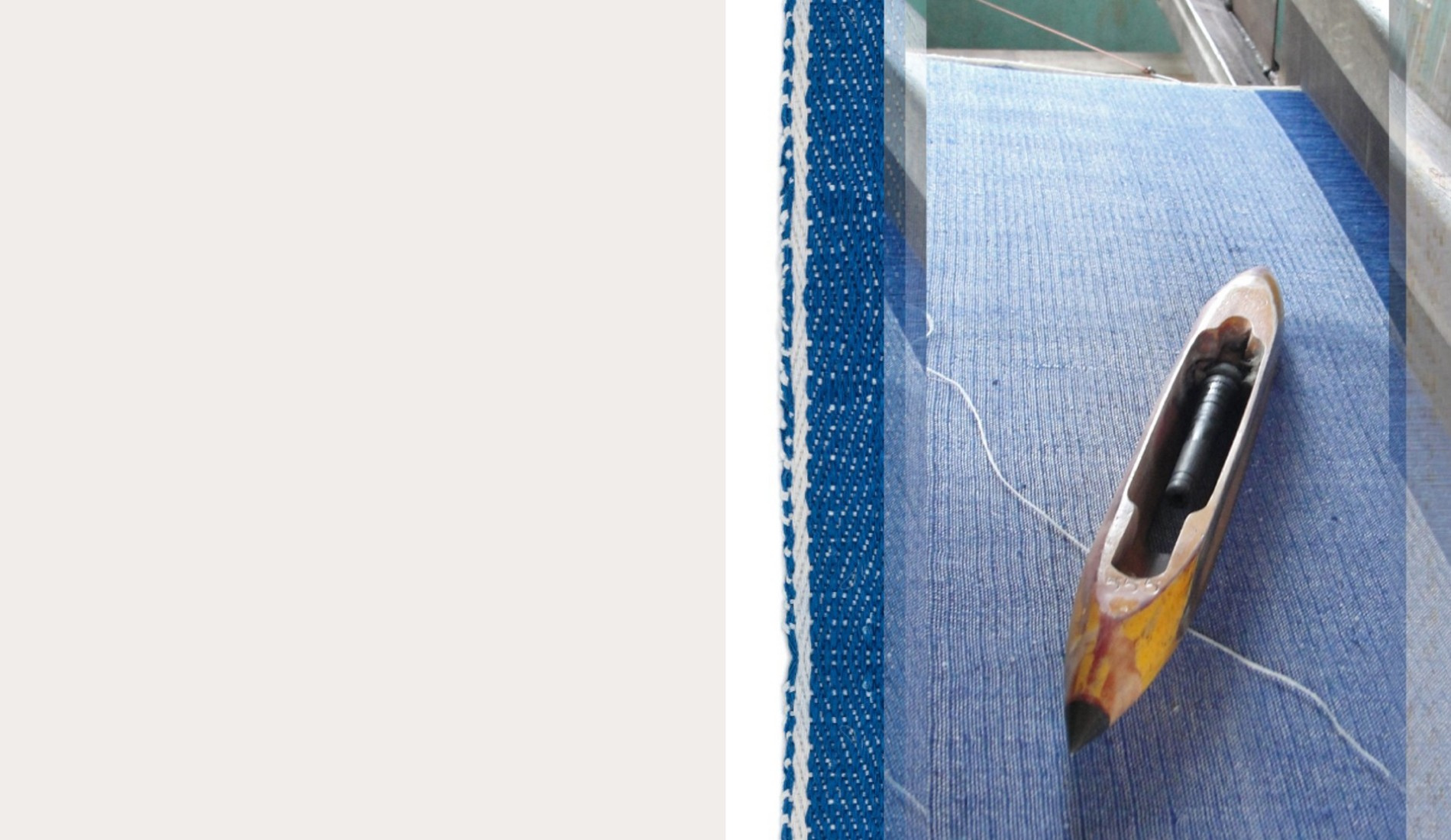

Handwoven denim

India’s Sam Vegetable Colours have an organic handwoven denim dyed with natural indigo whilst denim giant Arvind collaborates with village industries on khadi denim (hand spun and handloomed) of consistent quality.

Seven Senses also celebrates khadi, offered in a variety of weights from 3oz to 15oz and colours.

Image: Seven Senses

Handwoven denim

India’s Sam Vegetable Colours have an organic handwoven denim dyed with natural indigo whilst denim giant Arvind collaborates with village industries on khadi denim (hand spun and handloomed) of consistent quality.

Seven Senses also celebrates khadi, offered in a variety of weights from 3oz to 15oz and colours.

Image: Seven Senses

Handwoven Denim

Handloom Denim has mastered the production of handloomed selvedge denim. They offer a wide range of weights and colours in their online shop, as well as a full fabric sample kit.

5P Denim also specialise in handloomed fabrics, with a state of the art green facility housing 54 handloom machines in Chennimalai, India.

Image: Handloom Denim

Handwoven Denim

Handloom Denim has mastered the production of handloomed selvedge denim. They offer a wide range of weights and colours in their online shop, as well as a full fabric sample kit.

5P Denim also specialise in handloomed fabrics, with a state of the art green facility housing 54 handloom machines in Chennimalai, India.

Image: Handloom Denim

Buttons, Rivets & Zips

Metalbottoni’s No Impact production uses no synthetic chemicals, waterbased paints, reduced water & energy consumptions and is now applied to all their collections. Apholos have part and fully recycled metal buttons and rivets.

YKK's new GreenRise zippers are made from plant based plastic, an additional offering to their Nautulon® recycled range.

Image: Metalbottoni

Buttons, Rivets & Zips

Metalbottoni’s No Impact production uses no synthetic chemicals, waterbased paints, reduced water & energy consumptions and is now applied to all their collections. Apholos have part and fully recycled metal buttons and rivets.

YKK's new GreenRise zippers are made from plant based plastic, an additional offering to their Nautulon® recycled range.

Image: Metalbottoni

Sign up to connect with 50,000+ other sustainability-minded professionals and access over 300 pieces of actionable intelligence.

Common Objective is a global sourcing and information network that enables you to succeed in sustainable fashion business.